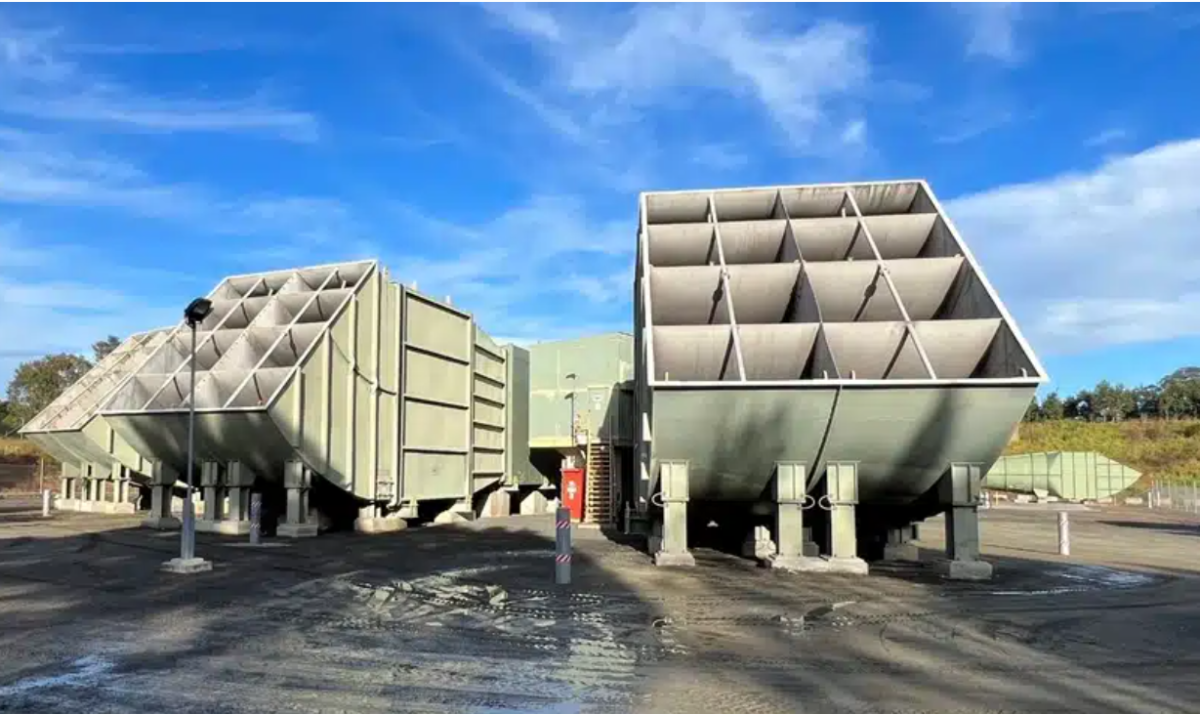

NSW Planning Minister and Wollongong MP Paul Scully says the NSW Government is proud to support GM3 to trial emissions reduction technology at Appin with approvals and a grant of up to $15 million. Photo: GM3.

New technology trialled in the Southern Highlands could reduce greenhouse gas emissions from coal mines.

The NSW Government has given Illawarra Coal Holdings Pty Ltd the go-ahead to build and operate a pilot regenerative thermal oxidiser at its Appin Mine ventilation site.

This system captures ventilation air and heats it to break down methane into carbon dioxide and water.

As a greenhouse gas, methane is between 28 and 80 times more potent than carbon dioxide, and the government estimates it will reduce the mine’s emissions by 36,000 tonnes of CO2 equivalent each year.

A 2023 report commissioned by the anti-coal group Lock The Gate and produced by clean energy think tank Ember found the Appin mine produces the equivalent of more than two million tonnes of C02 per year.

Minister for Planning and Public Spaces Paul Scully said the technology would help NSW achieve its emissions reductions targets while continuing essential industry.

“The approval of this modification allows the Appin mine to improve its environmental performance while continuing to provide coal for steelmaking,” he said.

“Innovations like this one reduce emissions to progress towards our legislated emissions reduction targets.”

The Bulli Seam Operations primarily produces metallurgical coal for steelmaking, a key component of domestic and international supply chains.

The approved modification does not change how much coal the project is able to extract, but it does include additional vegetation clearing and earthworks at the site 25 km northwest of Wollongong.

The mine employs around 1100 people, and construction of the oxidiser will create around 20 to 30 jobs over 12 months.

A spokesperson for GM3, which owns the mine, said the project would be a case study for the industry.

The demonstration plant and associated infrastructure will be located adjacent to our existing Appin Mine Ventilation Shaft No.6 at Douglas Park, within the Wollondilly local government area.

Construction is expected to be complete in 2027 and is supported by a grant of up to $15 million from the NSW Government’s Coal Innovation Fund.

But is 36,000 fewer tonnes of C02 any more than a drop in the bucket of a site that emits two million?

University of Wollongong’s energy authority, Ty Christopher, said it was a step in the right direction.

“This is a classic case of not putting perfect in the way of progress,” he said.

“If we accept that we’re going to make steel in Australia, the technology to do that requires coal and the coal seams in and around Wollongong are high quality metallurgical coal.

“We’re not able to make clean iron or clean steel yet globally, so we need to try to decarbonise our activities while we pursue research into how to make clean iron and steel.”

The University of Wollongong hosts a national research hub dedicated to making the steel industry more sustainable.

Until that research bears fruit, Ty said reducing emissions from metallurgical coal mines as much as possible is a step in the right direction.