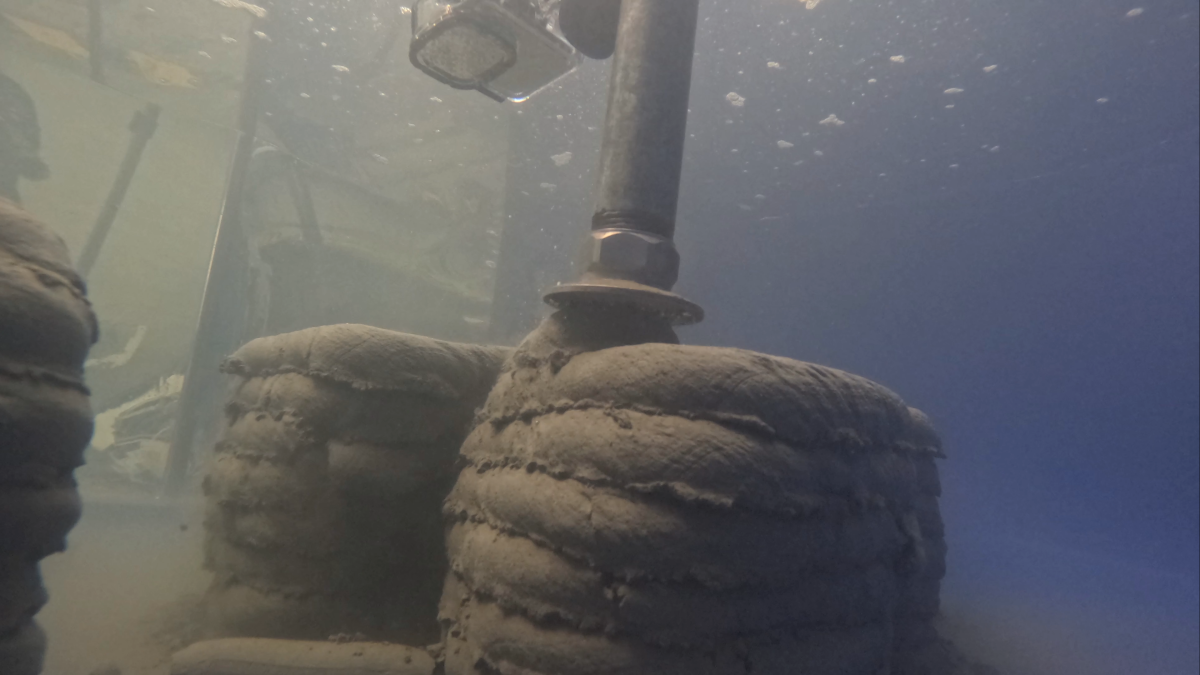

Have UOW researchers discovered the technology that will rebuild the world’s aging underwater structures — and maybe fuel a future building boom in outer space? Photo: LUYTEN 3D.

It sounds like science fiction: machines silently building structures beneath the waves, layer by precise layer, as fish glide past and currents pull at fresh concrete. But on Australia’s east coast, that future has already arrived.

In a collaboration between the University of Wollongong (UOW) and LUYTEN 3D, researchers have successfully created Australia’s first underwater 3D concrete printing system — alongside a world-first, accelerator-free, “single-mix” concrete designed to hold its shape and strength underwater without chemical shortcuts.

The breakthrough overturns decades of assumptions about how underwater construction must work. Traditionally, engineers have relied on rapid-setting chemicals or complex multi-stage processes to stop concrete washing away before it sets. This new system instead relies on material design — engineering the concrete itself to behave differently in water.

Project lead Dr Aziz Ahmed said the milestone was not theoretical — it was already working in real-world trials.

“To the best of our knowledge, this is the first underwater 3D concrete printing system developed and demonstrated in Australia,” he said.

“Our recent trials confirm that our single-mix solution is not just theoretically sound, but practically viable. It offers the structural integrity needed for real-world application while simplifying the logistics of underwater deployment.”

The implications stretch far beyond engineering curiosity. Around Australia and the world, vital infrastructure is ageing under increasing climate pressure. Ports, wharves, bridge supports and offshore structures face constant assault from saltwater corrosion, storms and rising seas. Repairing them traditionally means expensive dry docking, large marine works, or lengthy shutdowns.

Underwater printing changes that equation entirely. Instead of building structures on land and lowering them into place, engineers can print directly at the site, even in locations too dangerous or remote for divers. The system can potentially be mounted to remotely operated underwater vehicles, allowing experts on land to supervise construction happening hundreds of metres below the surface.

For councils and governments, the cost savings could be transformative. In traditional underwater projects, temporary formwork alone can account for up to 60 per cent of project costs. Removing it doesn’t just save money, it enables highly customised, site-specific structures built exactly where they are needed, with almost zero material waste.

The technology also opens unexpected environmental opportunities. By using biomimicry — designing structures to resemble natural marine habitats — printed concrete could double as artificial reefs or marine habitats, supporting biodiversity instead of displacing it. Researchers are monitoring water quality around printed structures to ensure no harmful substances leach into surrounding ecosystems.

Unlike experimental materials that never leave the lab, the new concrete mix was developed using an already commercially available base product, modified specifically for underwater printing. That choice was deliberate, ensuring the technology can scale globally, not just succeed in controlled research environments.

The project also pushes Australia to the forefront of a rapidly evolving global field. Some research teams, including those at Cornell University, have demonstrated underwater printing, but typically rely on multi-stage chemical processes that become harder to manage at depth or in strong currents.

For LUYTEN 3D’s global leadership, the work represents a turning point in how humanity approaches construction itself.

CEO Ahmed Mahil sees the technology as part of a much bigger shift.

“This is a completely new chapter for construction and manufacturing. Printing underwater fundamentally changes how we think about building, repairing, and strengthening critical infrastructure in marine environments.

“We’re moving beyond what’s possible on land. Underwater 3D printing allows us to address infrastructure resilience where it’s needed most, below the surface, whether that’s ports, wharves, defence applications, or other subsea assets.”

He said the lessons might even extend beyond Earth.

“This work is an early rehearsal for extraterrestrial construction. By learning to print in harsh, resource-constrained environments and using in situ materials rather than refined inputs, we are building the knowledge and technology needed for building on the moon using lunar regolith as a building material.”

The project’s success required a multidisciplinary approach from a diverse team of experts. Led by Dr Aziz Ahmed, the team included renowned structural engineering expert Professor Neaz Sheikh and research fellow Dr Sheikh Sakib, and marine biologist Professor Andy Davis and ‘Blue Economy’ researcher Dr Freya Croft, who investigated ecological safety.

They were supported by EIS Faculty Executive Dean Professor Gursel Alici, Head of School (Engineering) Professor Faisal Hai and of course, LUYTEN 3D, demonstrating advancement possibilities when academia and industry work together.

For now, the system has successfully printed multiple layers underwater and is moving toward commercial readiness. More funding and regulatory approvals will be needed before large-scale deployment — but the direction is clear.

Having already demonstrated its ability to reliably 3D-print multilayer concrete underwater, with stable structures and controlled curing, the platform is ready for real-world deployment, pending standard approvals, and is suited for marine infrastructure, defence and resilience projects.

For coastal nations facing ageing infrastructure, climate pressure and rising defence demands, the future of construction may no longer sit on land at all — but quietly assembling itself, one layer at a time, beneath the surface.